- ATR and Fly91 Sign New Eight-Year Global Maintenance Agreement

- Global Aircraft Hangar Door Specialist Jewers Doors deepens India Commitment with New Subsidiary

- Air India enters multi-year agreement with Boeing for component services program to support entire 787 fleet

- Air India converts 15 Airbus A321neo orders to latest generation A321XLR

GEnx: GE Aerospace's Technological Marvel

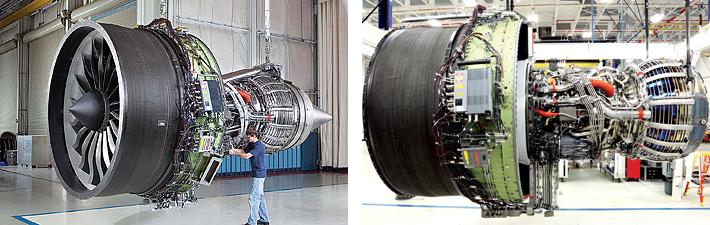

From composite fan systems and advanced combustor technology to digital maintenance ecosystems, the GEnx engine represents one of GE Aerospace's most ambitious and successful propulsion programmes

When GE Aerospace launched the GEnx programme in the early 2000s, the global aviation industry was entering a defining period of transition, with airlines demanding step-change improvements in fuel efficiency, emissions performance and dispatch reliability, and aircraft manufacturers designing lighter, longer- range widebody platforms optimised for new intercontinental and point-to-point routes. Conceived as GE's response to this inflection point, the GEnx—short for GE Next-Generation—was developed as the successor to the highly successful CF6 engine family, not as an incremental upgrade but as a comprehensive rethinking of widebody engine architecture.

The objective was to deliver a next-generation propulsion system capable of enabling the new class of long-haul aircraft while setting fresh benchmarks in efficiency, durability and environmental performance. Drawing on decades of experience from iconic programmes such as the CF6 and GE90, and leveraging advances in materials science, aerodynamics, combustion technology and digital monitoring, the GEnx was designed from the outset to power Boeing's newest widebody aircraft, including the 787 Dreamliner and later the 747-8, while achieving double-digit gains in efficiency and emissions performance compared with previous generations.

TECHNOLOGY LINEAGE AND CONCEPTUAL FOUNDATIONS

The conceptual foundations of the GEnx were laid in the early 2000s as Boeing advanced plans for the 787 Dreamliner and later the 747-8, prompting GE Aerospace to identify the need for a new engine that could deliver double-digit improvements in fuel burn and emissions while supporting longer flight cycles and higher utilisation. Rather than pursuing radical architectural risk, the GEnx programme drew heavily from GE's experience with the GE90—the world's most powerful commercial jet engine—refining and optimising its proven aerodynamic and core design principles for a very different performance envelope focused on sustained cruise efficiency, lower weight and extended durability rather than extreme thrust output. Officially introduced in the mid-2000s, the GEnx engine family progressed through extensive development, certification, endurance testing and real-world validation, including its first flight on GE's Boeing 747 flying testbed, before entering commercial service in the early 2010s as one of the most thoroughly tested widebody engines in GE's history.

COMPOSITE MATERIALS AS A STRUCTURAL BREAKTHROUGH

One of the most significant technological breakthroughs of the GEnx programme was the introduction of composite fan blades paired with a composite fan case, making it the first commercial engine to integrate both elements as a fully unified system— an advance beyond earlier applications where composite blades had flown on the GE90 but without a composite case. According to GE Aerospace, this composite fan system delivered multiple, simultaneous benefits: substantial weight reduction that directly improved fuel efficiency; enhanced corrosion resistance that increased durability; and robust structural containment capability that met stringent safety requirements while remaining lighter than traditional metallic structures. The reduced rotating mass of the fan assembly also lowered mechanical stress and loads across the engine, contributing to improved component life, greater long-term reliability, and marking a decisive shift away from conventional metal-dominated engine designs, while laying the foundation for wider adoption of composite materials in future propulsion systems.

ADVANCED AERODYNAMICS AND PRESSURE SYSTEMS

Beyond materials, the GEnx incorporates extensive aerodynamic optimisation across the fan, compressor and turbine sections, including advanced threedimensional aerodynamic modelling to minimise losses and improve airflow stability. The engine features a high overall pressure ratio derived from GE90 architecture, enabling more efficient compression of intake air and delivering higher thermal efficiency—an essential factor in reducing fuel burn during long-duration cruise segments. GE Aerospace has consistently confirmed that the combined effect of refined compressor aerodynamics and lightweight turbine materials enables the GEnx to achieve up to 15 per cent lower fuel consumption and CO2 emissions compared with the CF6 engines it replaced, with these performance gains validated through certification testing and reinforced by inservice operational data.

ENVIRONMENTAL PERFORMANCE AND THE TAPS COMBUSTOR

Environmental compliance was embedded in the GEnx design from the outset, with a key enabler being the Twin-Annular Pre-Swirl (TAPS) combustor, a lean-burn combustion system that premixes fuel and air more effectively before combustion. According to official GE Aerospace data, TAPS delivers nitrogen oxide (NOx) emissions well below international regulatory limits, while also improving fuel–air mixing to achieve cleaner combustion and reduced particulate emissions. This advanced combustor architecture not only ensures compliance with current environmental standards but has also proven particularly important as the aviation industry transitions toward greater use of Sustainable Aviation Fuel (SAF), for which the GEnx is fully compatible within approved blend limits, supporting long-term fleet sustainability and regulatory readiness.

SERVICE ENTRY AND GLOBAL MATURITY

Since entering commercial service in the early 2010s—first on the Boeing 747-8 in 2011 and subsequently on the 787 Dreamliner in 2012—the GEnx has built an exceptional service record and achieved one of the fastest adoption rates in GE's widebody portfolio. GE Aerospace has confirmed that the engine became the fastest-selling high-thrust engine in the company's history, accumulating tens of millions of flight hours across a global operator base spanning more than 70 airlines worldwide and powering multiple aircraft configurations. By 2023, the GEnx family had surpassed 50 million flight hours, reaching that milestone faster than any other GE widebody engine line, while regional achievements— including two million flight hours with South Asian airlines in 2024 and five million hours flown in Japan—further underscore the engine's operational maturity, reliability and widespread trust among airline operators.

CONTINUOUS IMPROVEMENT AND DIGITAL INTEGRATION

Continued investment in durability and reliability has been a defining feature of the GEnx's evolution well beyond entry into service. Extensive endurance testing—including more than 3,000 dust ingestion cycles simulating severe operating environments—has validated improvements in critical components such as the combustor and turbine blades, reinforcing confidence in long-term durability. These enhancements, supported by realworld operational data, are complemented by GE Aerospace's expanding global services and digital ecosystem, which integrates on-wing technologies such as 360 Foam Wash and AI-enabled inspection and diagnostic tools. Together, these capabilities enable predictive maintenance, extend time on wing, reduce maintenance burden and lifecycle costs, and improve overall performance optimisation, reinforcing the GEnx's value proposition for airlines beyond its initial fuel-efficiency gains.

A DEFINING ACHIEVEMENT IN ENGINE ENGINEERING

The evolution of the GEnx reflects a broader transformation in how commercial engines are designed, built and supported, with GE Aerospace combining advanced materials, refined aerodynamics, low-emissions combustion and digital services to deliver not just an engine but a complete propulsion platform aligned with the long-term realities of global aviation; rooted in GE's proven GE90 architecture and now forming the backbone of modern long-haul operations, the GEnx has redefined expectations for wide-body propulsion through its innovative use of composites, fuelefficient design and continual evolution driven by rigorous testing, anchoring both the performance and sustainability of many of today's most efficient commercial aircraft.