- ATR and Fly91 Sign New Eight-Year Global Maintenance Agreement

- Global Aircraft Hangar Door Specialist Jewers Doors deepens India Commitment with New Subsidiary

- Air India enters multi-year agreement with Boeing for component services program to support entire 787 fleet

- Air India converts 15 Airbus A321neo orders to latest generation A321XLR

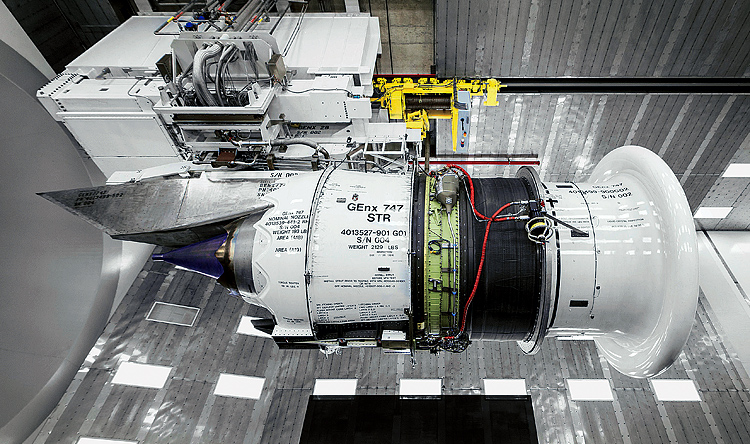

GEnx, the Preferred Engine for Long-Haul Flights

Fuel efficiency, reliability and sustainability define long-haul economics. The GEnx engine brings all three together, making it one of the most compelling propulsion choices in modern widebody aviation.

In long-haul commercial aviation, the engine is far more than a source of thrust; it is a central determinant of route economics, operational resilience and environmental compliance. Fuel burn, reliability, maintenance intervals and sustainability performance directly influence profitability, fleet utilisation and network flexibility on flights that can exceed 15 hours in duration. Against this demanding backdrop, the GE Aerospace GEnx engine has emerged as one of the most widely adopted and trusted propulsion systems for long-range widebody aircraft, designed specifically for extended-range operations and combining high propulsive efficiency, operational durability and future-ready sustainability in a package that closely aligns with airline priorities in an increasingly volatile fuel-price and environmentally focused operating environment.

FUEL EFFICIENCY AND LONG-RANGE ECONOMICS

Fuel is the single largest variable cost in longhaul operations, and GE Aerospace has confirmed that the GEnx delivers up to 15 per cent lower fuel consumption and CO2 emissions compared with the earlier CF6 engines it replaced. This efficiency advantage is driven by a combination of high bypass ratio design, advanced aerodynamics, lightweight composite structures, reduced engine weight and an optimised combustion system. For airlines operating intercontinental routes, even single- digit percentage reductions in fuel burn translate into substantial annual savings. The GEnx's improved efficiency enables longer non-stop operations without payload penalties, making previously uneconomical long-haul and thinner intercontinental routes commercially viable, while on ultra-long-haul sectors, marginal efficiency gains compound into significant operational and financial benefits over time.

RELIABILITY AND TIME ON WING

Long-haul networks demand exceptional engine reliability, as any unscheduled engine removal or in-service issue on a widebody aircraft can disrupt global schedules, strand passengers and trigger cascading operational and recovery costs. GE Aerospace data confirms that the GEnx delivers industryleading dispatch reliability, supported by robust component design, advanced materials, conservative thermal margins and extended time-on-wing performance. Continuous engine health monitoring and predictive analytics further enable the GEnx to remain in service longer between shop visits, reducing maintenance interruptions and keeping aircraft in revenue service for extended periods. This high level of reliability is particularly valuable for airlines operating long-haul routes from geographically dispersed hubs or across remote regions where access to maintenance infrastructure may be limited.

MAINTENANCE INNOVATION AND LIFECYCLE VALUE

GE Aerospace supports the GEnx with a comprehensive services ecosystem aimed at lowering total cost of ownership, combining advanced on-wing solutions and digital maintenance technologies. Key among these is 360 Foam Wash, which enables effective, water-free compressor cleaning, improving on-wing fuel efficiency, reducing performance degradation, minimising environmental impact and cutting maintenance downtime. Complementing this, AI-enabled inspection tools, digital health monitoring and predictive analytics allow airlines to anticipate maintenance requirements rather than react to failures, enabling more efficient scheduling of interventions. These capabilities are particularly valuable for long-haul aircraft operating far from base maintenance hubs, as reduced unscheduled maintenance enhances aircraft utilisation, supports more predictable maintenance planning and improves overall fleet economics.

ENVIRONMENTAL COMPLIANCE AND SAF READINESS

Environmental performance has become inseparable from long-haul viability and is increasingly shaping airline strategy. The GEnx engine addresses this requirement through its TAPS combustor, which reduces NOx emissions well below regulatory limits, while its lower fuel burn directly cuts CO2 output. GE Aerospace has also confirmed that GEnx-powered aircraft have successfully operated long-haul flights using approved Sustainable Aviation Fuel blends, demonstrating the engine's readiness for near-term decarbonisation. As regulatory frameworks tighten and airlines commit to net-zero targets, this ability to adopt SAF without hardware or structural engine modifications offers a decisive operational and strategic advantage, particularly as SAF availability expands and regulatory pressure intensifies.

OPERATIONAL FLEXIBILITY AND ROUTE EXPANSION

The GEnx has powered some of the world's longest commercial flights, including ultralong- range missions that test propulsion efficiency and durability, demonstrating its ability to sustain consistent performance across extended cruise profiles and varied climatic conditions. For airlines and network planners, this capability translates into greater network flexibility, enabling the Boeing 787 to profitably serve thinner long-haul routes, open new city pairs, reduce reliance on intermediate hubs, and respond more flexibly to changing travel demand, while leveraging the engine's range, payload capability and reliability to reshape long-haul networks in an increasingly competitive market.

WHY AIRLINES CHOOSE GEnx

The enduring appeal of the GEnx lies in its balance, integrating advanced technology with proven engineering and operational maturity to deliver efficiency gains without compromising durability or reliability. GE Aerospace's confirmed service milestones, growing installed base, and accumulating flight hours reinforce the engine's reputation as a dependable, future-ready solution for global aviation. As the company continues to enhance the engine through service innovations and digital tools, the GEnx remains fully aligned with both current operational requirements and long-term sustainability objectives.

CONCLUSION

For long-haul airlines navigating rising fuel costs, stricter environmental mandates and increasingly competitive route structures, the GEnx represents a propulsion system optimised for reality—not theory. In an era where long-haul aviation must reconcile economic pressure with environmental responsibility, the engine's fuel efficiency, reliability, sustainability credentials, maintenance and lifecycle support, and SAF readiness collectively make it one of the most compelling propulsion choices for modern widebody fleets—and a cornerstone of long-haul aviation today.