- Prime Minister Narendra Modi inaugurates Aero India 2023 in Bengaluru; Releases Commemorative Stamp

- Defence Secretary meets delegations from Saudi Arabia, USA and Oman on the sidelines of Aero India 2023

- Foreign Ministers of 32 countries to attend Aero India 2023

- Embraer showcases the C-390 Millennium at Aero India 2023

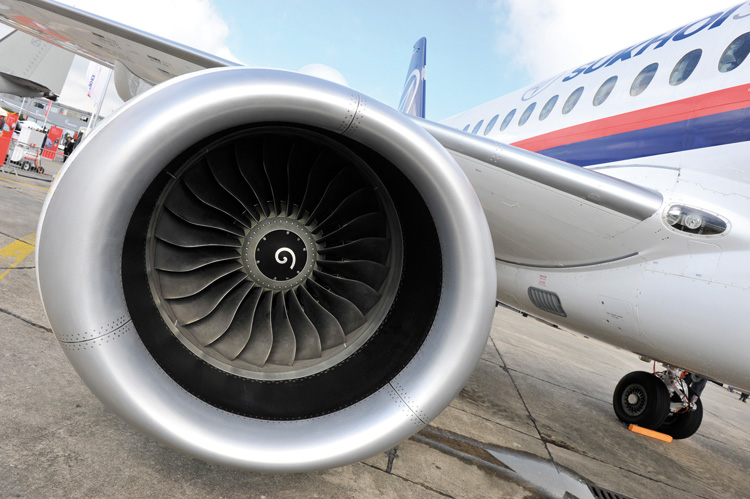

‘PowerJet delivers a complete propulsion system, comprising both engine and nacelle’

SP’s ShowNews (SP’s): What is the work-share arrangement between Snecma and NPO Saturn in respect of the development and manufacture of the SaM146 aero engine?

PowerJet: Snecma and NPO Saturn began to work together in 1997, when Snecma subcontracted the production of CFM56 engine parts to NPO Saturn. PowerJet, founded in July 2004, is a joint venture of Snecma, Safran Group of France and NPO Saturn of Russia. The company is in charge of all SaM146 programme management tasks, encompassing design, production, marketing, sales and support. PowerJet delivers a complete propulsion system, comprising both engine and nacelle. This implies the involvement of two other Safran group companies-Hispano-Suiza, in charge of the engine control system; and Aircelle, in charge of nacelle production. PowerJet is also the single point of contact for all customers, which means operators can count on a “one-stop shop” for all their propulsion system and support needs.

Snecma is in charge of the core engine, control system, accessory drive (accessory gearbox, transfer gearbox), overall propulsion system design integration and flight testing. NPO Saturn is responsible for the components of the low-pressure section, engine assembly and ground testing.

SP’s: What are the unique features of the SaM146 aero engine from PowerJet that powers the SuperJet 100? Does this engine meet the emission standards required for modern day aero engines?

PowerJet: The SaM146 is the only engine designed and developed from the ground up for the regional aircraft market. Its performance is tailored to the specific needs of regional airlines.

The SaM146 is a complete propulsion system, comprising engine, nacelle and equipment. Developing 13,500 to 17,800 lb of thrust, a single SaM146 engine covers an entire family of 70- to 120-seat aircraft. Airlines will reap the benefits of commonality and economies of scale. Operators can adjust the SaM146 thrust level by simply replacing a plug in the control system and changing the nameplate. This engine commonality for a family of regional aircraft means reduced cost of ownership, with savings in terms of spare parts, tools, mechanic and pilot training, and of course spare engine inventories.

The SaM146 engine is also designed to be kinder to the environment, by reducing fuel consumption and optimising the combustion cycle to significantly reduce CO2 and all other emissions, in particularly NOx.

SaM146 offers 10 per cent lower fuel burn than the competition, low direct maintenance costs, low cost of ownership, longer life on-wing and meets or exceeds the most stringent upcoming noise and emissions standards (including CO2 and NOx). The engine features a margin of 20 per cent on NOx emission compared to current CAEP/6 regulations.

SaM146 MRO will be provided exclusively by PowerJet, through the global networks of Snecma and NPO Saturn, via the PowerLife organisation. Power-Jet directly provides a full range of support services for the entire propulsion system (engine, equipment and nacelle).

Maintainability is designed into the SaM146 to ensure high reliability and facilitate every facet of servicing. The key to this improvement is not only a lower parts count and fewer stages, but also the incorporation of advanced technologies such as blisks, cutting-edge maintenance software, a design that supports on-wing maintenance and component changes, and an advanced FADEC.

Seven-year-old joint venture between Snecma of France & NPO Saturn of Russia

| 1997: | Snecma and NPO Saturn began to work together when Snecma subcontracted the production of CFM56 engine parts to NPO Saturn. |

| April 2003: | The SaM146 engine selected by Sukhoi Civil Aircraft to power its regional jet Superjet100. |

| July 2004: | Creation of PowerJet to develop and commercialise the SaM146 engine. |

| December 2005: | Aeroflot orders 30 Sukhoi Superjet 100 aircraft. |

| July 2006: | First engine ground test. |

| June 2007: | Start of engine testing on the open-air test cell. |

| December 2007: | Start of engine flight tests. |

| February 2008: | First ground test on the Sukhoi Superjet 100. |

| May 19, 2008: | First flight test of the SaM146 on the Sukhoi Superjet 100. |

| December 24, 2008: | First flight of second Sukhoi Superjet 100 prototype at Komsomolsk-on-Amur. |

| June 2009: | The SaM146-powered Sukhoi Superjet 100 lands at Le Bourget Paris Air Show. End of the second series of tests on a flying test bed |

| July 25, 2009: | First flight of the third Sukhoi Superjet 100 prototype. |

| May 26, 2010: | With the SaM146 passing its medium bird ingestion test, PowerJet completes all tests required for certification. |

| June 23, 2010: | The European Aviation Safety Agency (EASA) issues the Type Certificate for the SaM146 engine. |

| August 9, 2010: | The Russian certification body, Interstate Aviation Commission Avia Register (IAC-AR) issues the Type Certificate for the SaM146. |

| August 24, 2010: | Delivery of the first production-standard engine. |

| September 18, 2010: | Delivery of the first production-standard propulsion system. |

| November 4, 2010: | First flight by a production-standard Sukhoi Superjet 100. |

| January 17, 2011: | Interjet places firm order for 15 Sukhoi Superjet 100 long-range jets, and takes 5 options. |

| January 28, 2011: | Russian certification of the Sukhoi Superjet 100 |

| June 21, 2011: | New Business Jet version of the Sukhoi Superjet 100 regional jet, the SBJ, also powered by twin SaM146 engines. New orders for the SaM146-powered SSJ100: Blue Panorama Airlines and PT Sky Aviation. |

| July 2011: | Order by GazpromAvia and an agreement with JSC “VEB-Leasing” at MAKS Air Show |

| October 2011: | Order of two SBJ aircraft plus two additional options by Comlux. |

| January 17, 2012: | SaM146 1S18 engine certified by EASA |

| February 3, 2012: | Sukhoi Superjet 100 receives EASA Type certificate |

SP’s: What steps has the company taken to provide product support worldwide to the Superjet100 powered by its SaM146 aero engine?

PowerJet: PowerJet has developed a specific SaM146 support organisation called PowerLife ensuring fast and reliable access to information and assistance under any circumstances.

As a single point-of-contact for all support services, PowerJet customer support organisation and service draws on the extensive experience of Snecma (via CFM International as well as its own military engines) and NPO Saturn. PowerJet is setting up a state-of-the-art customer support and service structure that will meet all airline expectations. Reflecting the proven global expertise of CFM, this organisation is tailored to the regional jet market. It comprises a Customer Support Centre, technical assistance drawing on both parent companies, and a dense network of field representatives, based on infrastructures already deployed by Snecma and NPO Saturn

SP’s: Has PowerJet explored opportunities for powering regional jets other than the SuperJet100 and if so what are the possibilities in this regard?

PowerJet: The SaM146 was designed for a thrust range from 13,500 to 17,800 lb. The first application for this engine is of course the Superjet 100, but PowerJet would consider all possible applications for this engine, on both new aircraft as well as retrofits on current aircraft in the 70 to 120 segment.

SP’s: Has the PowerJet experience opened fresh avenues for collaboration between the European and Russian aerospace industries?

PowerJet: Snecma and NPO Saturn have set up many partnerships within the SaM146 programme. The VolgAero plant, inaugurated in October 2005, is a state-of-the art production plant. It includes over 10,000 square metres of workshops, plus another 2,500 square metres of offices. VolgAero primarily makes parts for the SaM146: fan disk, low-pressure spool, casings, HP, supports for bearings, intermediate casing, exhaust casing and all accessory components. The plant has three product lines-rotating parts; mechanical and mechanically-welded casings; and engine accessory components. It also offers shared facilities for chemical, thermal and surface treatments (plasma, shot-penning, sand-blasting, etc.).

In 2007, Snecma and NPO Saturn built an open-air test bench in Poluevo, Russia (near Rybinsk), to handle certification tests for the SaM146. This test rig covers three types of testing: performance, certification tests (operation in cross-wind, water, ice and bird ingestions), and acoustic certification of the propulsion system. The only open-air test cell for this type of engine in Europe and Russia, it can also handle other engines.

Many Safran group companies are also involved with Russian industry in the SaM146/Sukhoi Superjet 100 programme:

- Snecma: SaM146 engine

- Aircelle: nacelle and thrust reversers

- Hispano-Suiza: engine control system

- Microturbo: air turbine starter

- Techspace Aero: engine lubrication unit

- Cenco Inc.: open-air test cell

- Sagem: engine over speed unit

- Messier-Buggati-Dowty: Superjet 100 landing gear system

- Snecma Propulsion Solide : mixed flow nozzle