- Prime Minister Narendra Modi inaugurates Aero India 2023 in Bengaluru; Releases Commemorative Stamp

- Defence Secretary meets delegations from Saudi Arabia, USA and Oman on the sidelines of Aero India 2023

- Foreign Ministers of 32 countries to attend Aero India 2023

- Embraer showcases the C-390 Millennium at Aero India 2023

Israel Aerospace Industries’ RAM MkIII is rough and tough

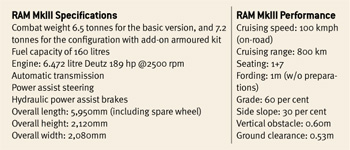

High performance, air-mobile armoured combat vehicle combining extreme off-road mobility, high reliability and affordability, the RAM from IAI/RAMTA has been delivering those attributes for more than 30 years, proving its worth as a multi-mission combat proven platform in service with numerous military forces throughout the world. Now delivering the latest generation RAM MkIII, the design is rooted to the pioneering concept of the mine-protected RBY platform, developed by Israel Aerospace Industries (IAI) during the early 1970s. A few years later, the Ramta Division of IAI adapted the basic design, and modified it into a multi-mission armoured personnel carrier and versatile weapon-carrying platform known as the RAM. The requirements defining this innovative platform are relevant today-a versatile platform offering adequate off-road mobility, basic and enhanced ballistic mine protection, high reliability and cost-effective life cycle cost. The RAM has been ordered and has been proven on real world/combat operations with more than a dozen military, paramilitary and police forces in Asia, Latin America and Africa, as well as supporting United Nations (UN) peacekeeping operations throughout the world.

VERSATILE COMBAT PLATFORM. The vehicle currently produced in its third generation RAM MkIII version, is maintaining all these attributes, with additional features added, adapting it to new missions. As a true combat vehicle, RAM MkIII features ballistic armour, counter-mine blast protection techniques and a firewall bulkhead, separating the engine compartment and fuel tank from the crew compartment, protecting the crew, weapon system and power-pack. The vehicle maintains a low silhouette and reduced weight, offering superior battlefield survivability, land and air mobility necessary for special insert missions. The basic RAM maintains an integral blast-protected belly design and all-round ballistic protection, employing the ‘diamond shape’ for deflecting mine blasts away from the vehicle and defeating 7.62mm AP and 0.5” ball threats. The vehicle is offered in two ballistic versions and over 20 configurations.

In the event of a mine blast, the armoured hull remains intact; being virtually separate from automotive section and the wheels. The geometric profile of the hull also enhances the vehicle’s resistance to such a mine blast. Once the wheel of the vehicle activates a mine, the explosion damage cuts the respective axles and the fibre glass fenders disintegrate, allowing the force of the blast to be directed outwards and away from the crew cabin.

ADVANTAGES OF THE REAR-MOUNTED ENGINE. The rear engine compartment represents a unique feature of the RAM. Unlike other armoured vehicles, which have the engine at the front or under the protected cabin, RAM places the entire power-pack engine, automatic transmission and transfer cases at the rear. Forward or central engine placement has significant implications for an armoured vehicle, potentially increasing vehicle height, exposing the vulnerable power-pack to physical and ballistic threats.

The RAM’s rear-mounted air-cooled engine solves these problems, offering additional benefits, especially in facilitating field maintenance by providing simple and quick access to the engine, gearbox and drive train. An armour-protected forward engine would often require complex support systems, employing spring-loaded lifting systems, or special tools and support, complicating routine maintenance activities. The air-cooled diesel engine demonstrates remarkable performance with very high reliability, requiring minimal logistic support.

The Deutz air-cooled engine has provided the heart of the RAM automotive system since the 1980s. This power-pack has demonstrated very high reliability in continuous and extensive operation under extreme field conditions. It offers many advantages for military operators, particularly its operational endurance in extreme tropical and/or desert temperatures, high mean-time-between-failure (MTBF) and low maintenance requirements.

Maintaining a 28.3:1 power-to-weight ratio with the powerful engine provides a major factor in the RAM’s cross-country mobility. The large wheel size complements this power to deliver superior agility. “To maintain its high mobility at the level required for the RAM we chose the largest tires we could use,” explained RAM Project Engineer ZviZuk, “We selected the 12.5 x 20 MPT-considerably larger than those used on most other vehicles of this type. They deliver extremely high mobility over rough terrain, in mud, snow and sand, without the use of heavy, complex and expensive independent suspension. Approach and departure angles, and low centre of gravity with high ground clearance provide the vehicles with high manoeuvrability and stability”.

Another unique attribute of the RAM MkIII is its undercarriage design. Unlike many conventional armoured vehicles built on commercial chassis, the RAM forms around a structural skin (Monocoque hull), which is built of two pieces of diamond-shaped ballistic steel.

Ramta offers the RAM MkIII exclusively with automatic transmission, selectable 2x4/4x4 drive modes, with or without differential locking, depending on customer requirements. Ramta maintains this flexibility to meet requirements for ultimate simplicity, in order to support customers in developing markets, where the users seek to minimise the skills needed to operate and support its vehicles. The vehicle is offered in open or closed cabin versions, configured in armoured personnel carrier, command vehicle, scout vehicle, weapon and missile carrier, air defence vehicle, mortar carrier, and is even offered with a special weapons and tactics (SWAT) configuration, complete with tactical assault ladders for multi-story breaching operations. The RAM has also been manufactured in both full and short configurations per customer demands.

TAILORED SOLUTIONS. “By minimising the part count required for each production kit, IAI Ramta maintains a lean production line able to quickly and efficiently modify, adapt and produce the platforms to meet specific customer requirements, even for small production quantities,” explains Rafi Jahn. “By relying on our plant’s computerised CAD/CAM and NASTRAN programmes, these modifications can be tested, verified and approved by our vehicle designers and automotive engineers prior to the production of the modified platforms.”

The RAM MkIII is designed for air mobility in medium transports including the Antonov 12 and C-130, both of which can carry two long vehicles or three short versions. “So far we have designed and produced over 20 different models of the RAM,” said HagaiShmuel, Ramta’s Marketing Manager. “We developed our production line to support small to medium quantities, characteristic of typical military orders. We can quickly gear up to produce the RAM MkIII in small batches in a short period of time, delivering dozens of vehicles within a period of a few months.”

The basic design offers mine protection meeting STANAG 2A and 2B level, and ballistic protection conforming to STANAG 2 or 3, depending on customer requirement. Because the entire vehicle and its ballistic protection package are designed, integrated and manufactured by the same group, Ramta has the flexibility enabling it to increase the level of armoured protection with add on armour kits without unknown variables potentially compromising performance.

This holistic approach to the vehicle has allowed Ramta to develop and successfully test protection kits specifically designed to defeat a wide range of threats (IED, mines, small arms, etc).